QUALITY

Zero-Defect Philosophy. Global Certifications. Trusted by Industry Leaders.

Quality is not just a policy at Hardy Fasteners—it’s a discipline practiced company-wide. Our Quality Management System (QMS) is certified to ISO 9001:2015 standards and continually evolves to meet the dynamic demands of global markets.

Core Pillars of Our Quality Assurance:

Supplier Qualification:

We source only from approved mills and vendors with material traceability and certification. All incoming raw materials are tested for chemical composition, hardness, and grain structure.

In-Process Quality Control:

Continuous monitoring at each production stage — from forging to thread rolling and surface treatment. Digital dashboards track key performance indicators in real-time for faster decision-making.

Final Inspection & Documentation:

100% inspection of critical dimensions and torque ratings. Visual and functional testing before packaging. Accompanied by Mill Test Certificates (MTCs), compliance reports, and customer-specific quality plans.

Compliance & Certifications:

ISO 9001:2015 | RoHS and REACH Compliant | NACE MR0175 (for oil & gas grade fasteners) | ASTM, DIN, BS, IS and custom specifications available.

Continuous Improvement:

Lean Manufacturing and Six Sigma methodologies deployed. Customer feedback loops integrated into QMS audits. Ongoing training for staff on the latest quality and safety standards.

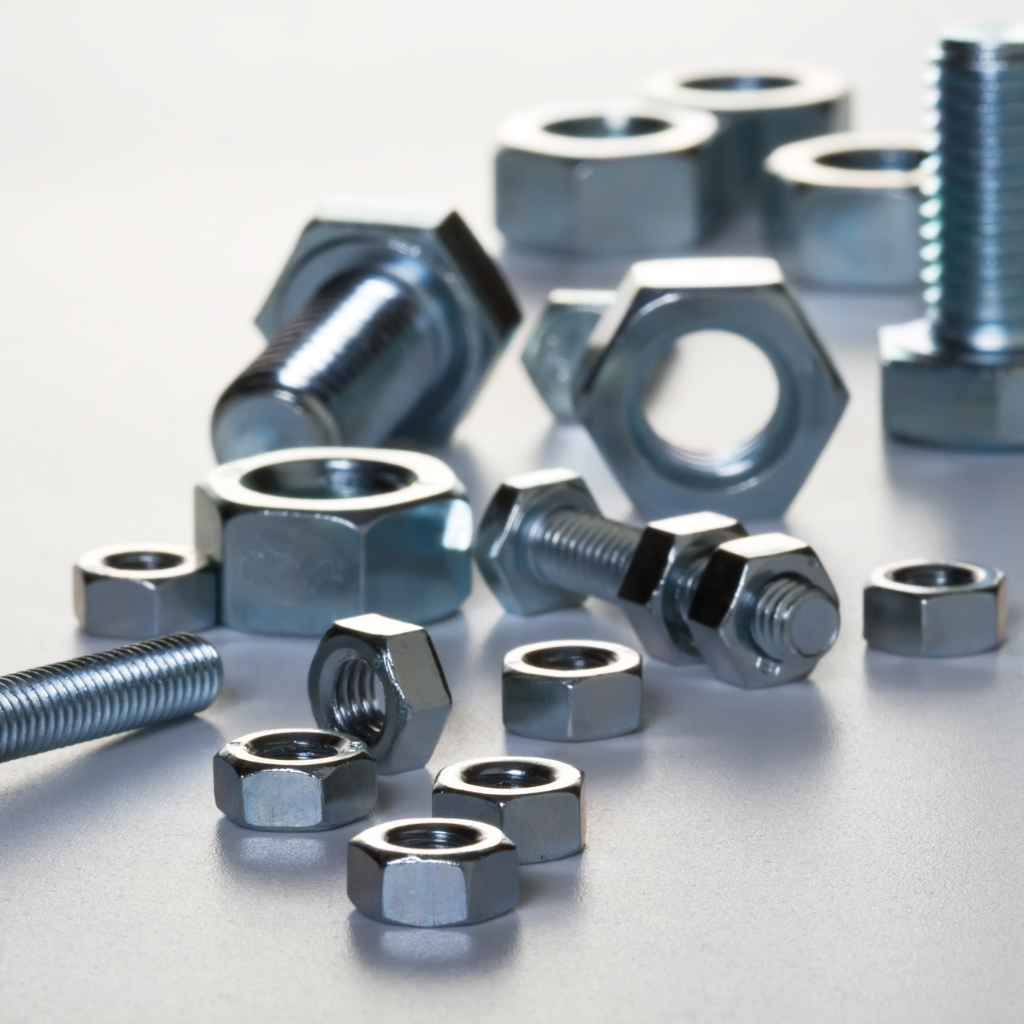

OUR PRODUCTS

Explore Our Range of Precision Products

Screw it, let's do it! Quality fasteners for every project.

At Hardy Fasteners, we take pride in our two-decade-long journey as a leading manufacturer of high-quality fasteners. Established in 2001, our commitment to precision engineering and exceptional durability has made us a trusted name in the industry. Explore our wide range of fastening solutions designed to meet the highest standards of performance and reliability.”

Subscribe Now

Don’t miss our future updates! Get Subscribed Today!

Business Queries: Info@hardyfasteeners.com

©2025. All Rights Reserved by @HardyFasteners